State Patent Product

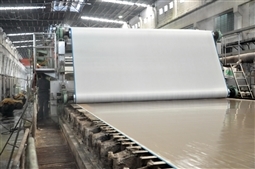

No Drive and Roll Top Former

No drive and Roll top former consists of lower formation roll, upper formation roll, water scraper box, suction transfer box, guide roll, stretch roll, wire suction box, lower pressure shower, high pressure shower, four leading roll and frame. Lower formation roll, one leading roll and upper formation roll are installed outside and inside of top wire separately. These three rolls form the nip with top wire and bottom wire. These rolls squeeze wet paper and make wet paper dewater rapidly. Water scraper box is installed above the nip. White water scraped from wet paper crosses one slope and enters into water scraper box, finally white water chest. Water scraper box can adjusted up and down for changing wire. Two leading roll guiding top wire in and out the nip can be adjusted horizontal and vertical in order to control angle of top wire and bottom wire. Upper formation roll can be adjusted up and down in order to control the degree of top wire embedded in bottom wire and the tension of two wires. Through these ways people can adjust dewatering quantity of top former and dewatering distributing of sheet two sides, optimize sheet forming, improve sheet formation.

Two formation rolls, stretch roll and one leading roll are installed with doctors in order to clean water and fiber of rolls surface. Frame includes four columns, two beams and two cantilevers. Two columns in front side include two movable blocks. Top wire can be changed by cantilever type. Top former has no drive and can be driven by bottom wire.

Before wet paper enters into the nip of top former, low suction boxes are installed in front of the nip to control consistency of wet paper. One suction transfer box is installed behind the nip to make sure wet paper go with the bottom wire.

Because roll top former consists of rolls, It can reduce power consumption of Fourdrinier section and wear of wire. Roll top former can greatly accelerate dewatering of Fourdrinier section greatly and increase the velocity of machine. About 25~35% water of sheet can be dewatered by top former. Roll top former installed in Fourdrinier section can cut down the amount of high vacuum boxes, increase the life of wire, decrease two sidedness of paper and improve paper formation. Of course it is also very convenient for installation and operation. Without doubt it is a very ideal choice for low speed paper machine(less than 800m/min).

The Advantage of Our Top Former Comparing with Other Type Top Former

|

Item |

Our Top Former |

Other Top Former |

|

Friction type between wires and dewatering elements |

Rolling friction |

Sliding friction |

|

Power for driving top former |

Be driven by bottom wire easily |

Require the electric power |

|

Dewatering principle |

Water of sheet is dewatered by squeeze of two wires. About 25~35% water of sheet can be dewatered by top former, so it needs few high vacuum boxes for dewatering behind top former. |

Water of sheet is dewatered by high vacuum and squeeze between wires and dewatering elements. |

|

Use life of wire |

Long,Rolling friction can reduce wear of wires and is better for use life of wire than sliding friction |

Short |

|

Operation |

Simple、convenient |

inconvenient |

Power consumption comparison of two paper machines in Xinxiang Xinya paper mill

|

Items |

PM1(with top former) |

PM2(without top former) |

Saved power consumption |

Percentage of saved power consumption |

|

Speed(m/min) |

420 |

400 |

||

|

Basis Weight(g/m2) |

70 |

57 |

||

|

Electric power consumption of Fourdrinier section couch roll (kW) |

16.72 |

17.86 |

1.14 |

6.38% |

|

Electric power consumption of Fourdrinier section driving roll (kW) |

16.72 |

19 |

2.28 |

12% |

|

Electric power consumption of vacuum pumps for Fourdrinier section vacuum box (kW) |

18.5 |

37 |

18.5 |

50% |

|

Electric power consumption of vacuum pumps for Fourdrinier section couch roll (kW) |

132 |

132 |

0 |

0% |

PM1 and PM2 of Xinya paper mill are also 2640 Fourdrinier machines with the same design speed 600m/min and the same product offset sheet. In 2005 our top former was installed in PM1. It is very successful in reducing power consumption of Fourdrinier section、accelerating dewatering of Fourdrinier section、increasing the velocity of machine and improving paper formation. Operating speed of PM1 was raised to 580m/min after top former was installed. In 2006 the same top former was installed in PM2.

Compared with other type top former, our top former can reduce power consumption of Fourdrinier section and doesn’t need vacuum pumps. On the contrary, other type top former will increase power consumption of Fourdrinier section greatly and needs vacuum pumps. You may know these data from the projects of other top former.

Power consumption comparison of our top former and other type top former

|

Items |

Our top former |

Other type top former |

Saved power consumption |

Percentage of saved power consumption |

|

Speed(m/min) |

900 |

900 |

||

|

Basis Weight(g/m2) |

70 |

70 |

||

|

Electric power consumption of top former (kW) |

0 |

~150 |

150 |

100% |

|

Electric power consumption of vacuum pumps or fans for top former (kW) |

~90 |

~160 |

~70 |

~44% |

|

Electric power consumption of Fourdrinier section driving roll after top former installed (kW) |

~176 |

~210 |

~34 |

~16% |