State Level New Product

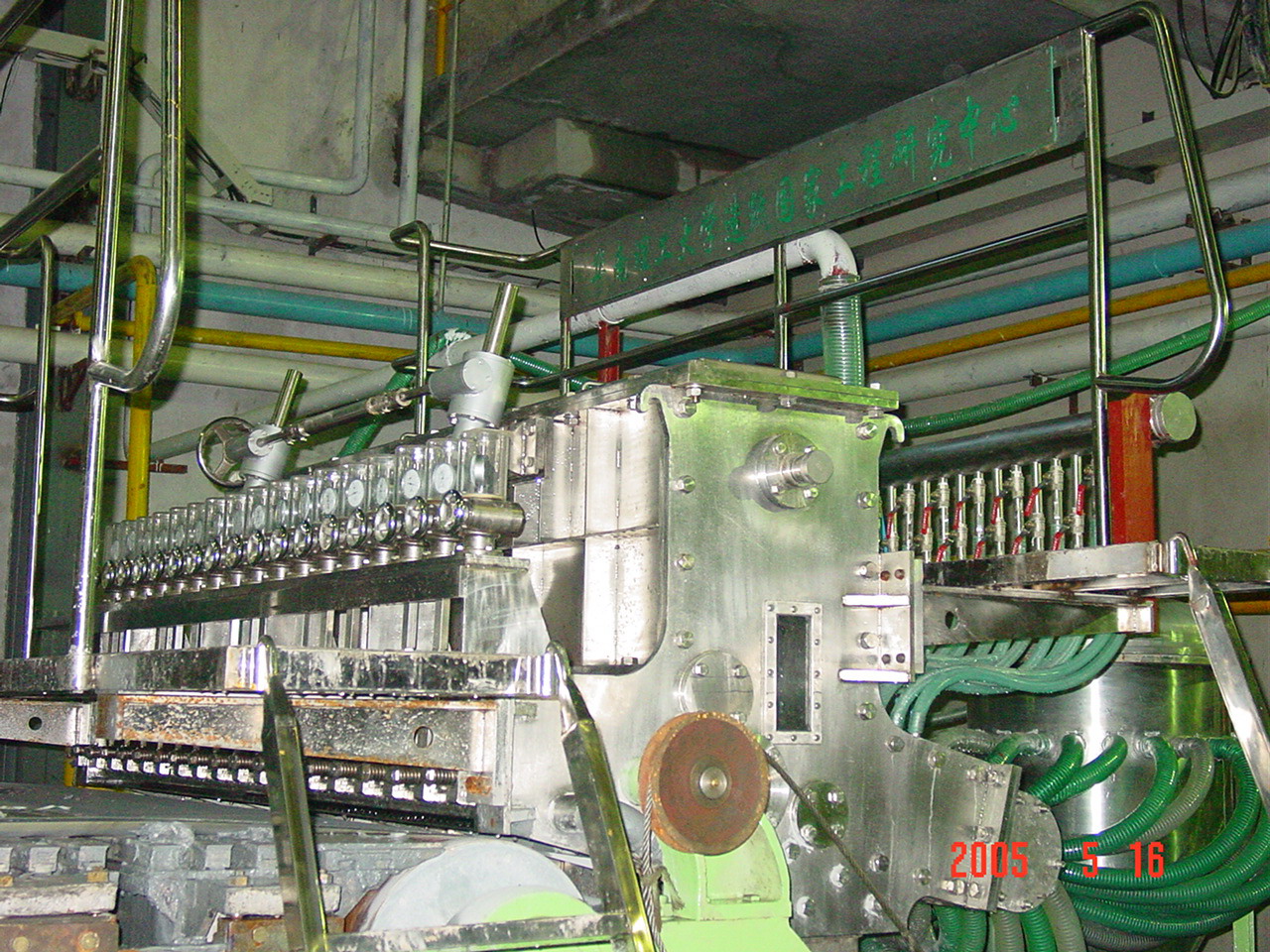

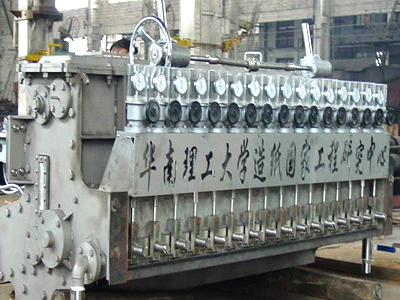

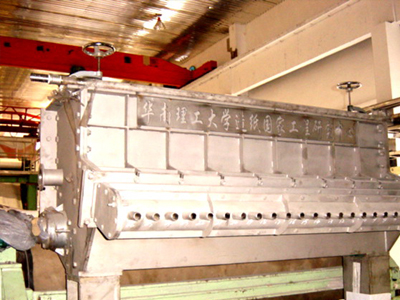

High efficient head box

High efficient head box was developed by south china university of technology with state -level patent products: step diffuser (Tapered distributor was used when the paper machine becomes wide), high efficient step diffuser with taper, holy roll or tube bank rectifying, According to research in lab for 20 years, we designed the rectifier cell and pond detailed and scientifically. We can control the quantitativeness of dilution water well, High sensitivity, faster control speed and short time. The equipment can regulate the uniformity of the profile basis weight and keep the uniformity of profile fibers effectively. The head box has many features such as the simple structure, easy for clearing, products in series. The series includes specify head box with super low speed, open head box with low speed, air-cushioned head box with middle and low speed, Hydraulic head box with high speed,inclined wire head box, multi-layer head box and so on. We have purposes to design the fourdrinier according to the different types of pulps and different speed of paper machine.

一、 Structure Specification of High Efficient Head box

1.1 Step diffuser: Patent No. ZL2004 20043504.3

1.1.1 Structure and Functioning Mechanisms of Step Diffuser

The new type of step diffuser is a conecylinder which is different from other head-boxes. The step diffuser must be used with the specify head box which plays a role effect for the uniformity of the profile basis weight. The step diffuser is made up of lower cone, damping element, setting chamber, up cone, flooding pipes , branch pipes and so on. Step diffuser is in series with head box with hoses.

1.1.2 The Performance Analysis of Equipressure Diffuser

Comparing with the traditional tapered distributor, the step diffuser has these features:

1) The step diffuser is produced easily, has high machining precision and be easy and simple to handle

2) The pulps go directly from diffuser to head box without abrupt direction change which can avoid some negative influences including uniformity of pulps and fibers’ directions because of direction change.

3) The velocity ratio can be 4:1 in the head box because the pulps can entry the head box with lower speed which has higher velocity ratio than normal head box. The step diffuser can change the flow rate with wide range to satisfied with the head box so that it can improve the the profile basis weight.

4) The overflow mouth is whether to be closed and the size of the front opening is whether to be controlled which have not effect on that the pulps go into the head box from step diffuser with equipressure and constantspeed. But the normal Tapered distributor need to regulate the press uniformly with circumfluence which is faster or lower can impact the direction change of fibers and pulp equally distribution.

1.2 Explosion Diffusion Room

The head box uses the inflow pulp with multi-tube, explosive rectify to pulp which is a new and high efficient type. At the same time, it is the key position of the head box. The size of structure can be regulated according to customers’ requirements. The design is designed by computer based with fluid test. The step diffuser can’t keep the uniformity of the profile basis weight but also enlarge the head-box’s applied range.

The equipment of step diffuser can be opened to clean.

1.3 Step Diffuser: Patent No. ZL93114134.6

The diffuser element is the injective diffuser with cone in the head box’s pond. Diffuser and pond have some angle which can reduce stagnation largely in the pond and avoid fibers’ flocculation.

1.4 Box

The box is made up of pulping zone, balancing chamber, rectify zone and lip of slice zone. There has been a great effect on properties of pulping and forming about boxes, shapes and sizes. If the box runner is too long, it will have maelstrom, cross flow and stagnation area which make fibers accumulated and liquid turbulence. The pulp will not be rectified and deenergized effectively if the cross flow is too short. If that, it will make liquid changed and air bubbles come. Shape and size of box is combined with the properties of infirmity directly. The shape and size of the head box are ascertained by step diffuser elements, balancing chamber, turbulent elements and other factors.

There is a viewing mirror on the side plate of head box’s work side. The all of the series operation side and driving side have pressure tap except open head box. These taps are used to install pressure sensor so as to be controlled by computer. There are intake tubes and exit tubes with compressed air in air-cushioned head box and specify head box with super low speed which can adjust for pressure. Two rectangular viewing mirrors are on the capping of the head box. There is an O ring between capping and box.

The top lip of the slice of the head box is often combine lip plate.

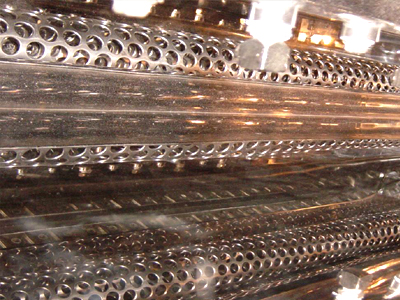

1.5 turbulent flow element

There is a rectifier roll at the region of convergence between balancing chamber and the lip of mouth in air-cushioned head box, open head box and super low speed head box. According to the specific processing parameter, we can confirm the diameter of rectify roll, diameter of holes and opening ratio. Holes are often arranged by bipitch. The rectify roll is driven by electric machine through worm gear. The rotate speed is regulated by variable frequency motor. At the same time, we can regulate the rotate speed according to the practical situation.

1.6 The size of opening of regulating equipment on top lip of slice

1.6.1 The regulating of top lip of slice with whole equipment

The size of opening on top lip of slice of the head box is regulated by two big Worm-gear cases and link gears on the top of the front

It will be moved up 0.2mm when the adjusting handwheel turns one round. Clockwise turn is moving up, anticlockwiseturn is bringing down. The adjusting equipment is controlled by motor-driven or manual operation.

There have an O ring between the two sides of the top lip of slice and side plate so as to avoid pulps running out.

1.6.2 The slight regulating of top lip of slice

The properties of lip of slice are key element of head box, meantime they have effect on the uniformity and profile basis weight directly. There are some micro-adjust fixtures are spaced apart from each other 100mm~110mm which can make the top lip of slice finely adjusted. It can regulate the size of open of the spouting mouth so that it can regulate the deviation of the profile basis weight.

We must take care of the top lip of slice because it is a fine and key element. The forming will be impacted if the location of the top lip of slice has been broken or adhered pulps. The location of the top lip of slice is very sharp, so we do not touch it and use metal to touch it. We should use cotton or others to clean it.

1.7 Bracket of head box

The brackets of head box can be moved up or down, front or behind. In order to adjust the jetnitpoint and jet angle, the equipment can regulate the relative position between spouting of stock mouth and wire.

1.8 Pressure regulating system

Hydraulic head box is controlled only by total pressure. The Control Pressure System of air-cushioned head box and specify head box with super low speed has two parts.

The first is total pressure control system.

The second is the level control system.

The pressure force of air-cushioned head box is supplied by root’s blower or other air supply which can keep the air cleanly and stable pressure.

The Control Pressure System of head box can be controlled singly, it can be combined with the paper machine’s DCS so as to achieve autocontrol as well.

1.9 Regulating system of the base weight of web of dilution water

The first Patent No.ZL200620059755.X; The second Patent No.ZL200610036394.1

At present, paper making technology has made progress in the whole world, the speed is improved very quickly, at the same time, the width is up to 10m. the paper quality is required the higher and the higher by the market especially in printing industry. Meantime low weight paper is the main trend for saving raw material. Though we face the challenge, we must have the profile basis weight and fiber distribution improved one level in paper making. In order to fulfill above-mentionedrequirements, we must use the new way to regulate pulp not to use the traditional lip of slice regulating.

There are many advantages as follow if you use dilution water to regulate profile basis weight.

1.9.1 white water recycled and used, reducing emission 00

Using dilution water to regulate basis weight of profile. One hand it can improve the concentration of pulp and decrease the usage of water. The other hand dilution water absolutely can be dilution white water which is from wire so that which can promote the recycling of white water, reduce the emission of white water and handling expenses. The method is a necessary road for zero emission.

1.9.2 Paper with low weight, saving raw materials

Dilution water regulates basis weight of profile which has more effect on improving the distribution of profile basis weight and greatly decreasing the deviation of profile basis weight. The method can improve uniformity and distribution of the fibers which can make fibers combined better and avoid accumulating and scatter for binding force. So we use the dilution water head box to produce papers which have stronger strength. This can give some chances for papers with low weight and using bad raw material to produce advantage products so that it can reduce the usage of raw material and decrease the cost of production.

1.9.3 Improving the paper quality and operation efficiency, reducing the distortion of head box

Attraditional regulating method about the lip of slice of head box has some disadvantages such as bad accuracy of adjustment, low sensitivity, and easy distortion about lip of slice and so on. When you regulate the profile basis weight, it has conflicts with the fibers direction which damages the direction and make the uniform of profile basis weight improved higher level.

So in order to overcome as above disadvantages, we use dilution water head box to regulate the pulps. We add dilution water regulating equipment through the step diffuser’s tubes on the head box. The equipment can regulate the concentration of local pulp so that it can improve the local basis weight of paper. The local dilution water of the design is added on the isostatic pressure, dilution water requires the water not to block the hose and water valve. The water can be weak white water filtered or clear water. At the same time we should make sure that the water pressure is stable. The water pressure is 0.3MPa~0.5MPa.

Interlockingly controlle. Dilution water control system auto-regulate the water by using the basis weight of QCS and real time data so that the profile basis weight become full-automatic regulating. In order to reach the goal, the QCS must supply communication protocol and the detection of QCS must be accurate. At the same time it can be controlled by hand. You can open and increase the related valve gate when the profile basis weight may be on the high side. If you do that, the concentration of pulp will be diluted. On the contrary, it is the same theory.